Assistant Professor

Ganpat University, Mehsana

Dr. Harshadkumar Patel was born in 1986, in India. Currently, He is working as an Assistant Professor in the Mechanical Engineering Department, at Ganpat University- U.V.Patel College of Engineering, Mehsana, Gujarat, India. He received a B.tech degree in Mechanical Engineering from Government engineering college, Bhuj, K. S. K. V. Kachchh University, Gujarat in 2008, M.tech degree received from U. V. Patel college of engineering, Ganpat University, Mehsana, Gujarat in 2012. He honored his Ph.D. Degree from Ganpat University, Gujarat in 2020. He filled 3 Patents and 6 Designs in the IPR section among that 2 Patents and 4 Design Granted. He guided more than 5 robots for different national and international competitions such as e-Yantra Ideas and Robocon Competition. He Organizes or works as an expert in more than 71 workshops and seminars in various colleges. He was awarded Global Faculty Award- 2023 given by AKS Worldwide Pvt. Ltd. in Nov 2023. He was also honored with the “Best faculty award” 4 times by Smt. S. R. Patel Engineering College, Unjha. He won more than 27 awards in different technical events, science fairs and organizations. He published a total of 12 papers in the International Journal and 12 papers published at the conference. He attended 8 Short term training programs (STTP), 22 Faculty development programs (FDP), 15 Workshop participation, 26 Seminar/Certified Webinar attended, 6 Professional training and 20 Event participations. He finished 9 Sponsored Projects and 5 Client based Projects. He guided 71 Projects in still academic life. His 28 press notes were published in all Gujarat newspapers such as Gujarat Samachar, Sandesh, Kutchch Press, Divya Bhaskar, etc. and 4 TV News presents in all state-level TV news.

He strongly believes in Love. His favorite own thought is “Today is Workday”.

Ganpat University, Mehsana

GoalDone Solution, Mehsana

Smt. S. R. Patel Engineering College, Unjha

K. D. Polytechnic, Patan

Man Industries, Khedoi, Anjar

GoalDone Solution, Mehsana

The Indian Society For Technical Education

International Association of Engineers

The society of mechanical & automotive engineers

Ph.D. in Mechanical Engineering

From Singapore University

Ph.D. in Engineering and Technology (Mechanical)

From Ganpat University

Master in CAD-CAM

From Ganpat University

Certificate Course in CCC+

From K. D. Polytechnic, Patan

3 Month Training on Pro/E Foundation

Paras CAD-CAM-CAE Center, Ahmedabad.

Bachelor in Mechanical Engineering

From Kachchh University, Kachchh

3 Month Training on C and C++

From Rakshak Computers, Bhuj.

HSC in Science Stream

From S. V. High school, Kadi

SSC with Technical Stream

From D.A.Patel Technical School, Kadi

At present Industrial application needs the use of advanced materials like tool steels, super alloys, ceramics, and composites with high precision and high surface quality. These materials are hard and difficult to machine. To meet these challenges, non-conventional machining processes are being employed to achieve higher metal removal rate, better surface finish and greater dimensional accuracy.

My Research work on Wire electric discharge machining (WEDM) is a specialized controlled discrete spark erosion non conventional machining process capable of accurately machining parts having complex shapes irrespective of material hardness. WEDM becomes a competitive and economical machining option which fulfills the requirement of short product development cycle. This process is affected by so many control parameters.

Also do on Varies Type Optimization methods, Different Types of mathematical Modeling, Design and Development of Non Conventional Machine etc.

In technolab work approximate 67 peoples from august 2002 to still now. All friends work on very heartily with day and night at varies palace as physics lab at sv highschool-kadi, model room at srpec-unjha and govt. Engg. College-bhuj. Also work on different projects like auto missile launcher, automatic rain measurement, development automatic foundry, computerized seismic measurement etc.

At present Industrial application needs the use of

advanced materials like tool steels, super alloys, ceramics, and

composites with high precision and high surface quality. These

materials are hard and difficult to machine. To meet these

challenges, non-conventional machining processes are being employed

to achieve higher metal removal rate, better surface finish and

greater dimensional accuracy.

Wire electric discharge machining

(WEDM) is a specialized controlled discrete spark erosion non

conventional machining process capable of accurately machining parts

having complex shapes irrespective of material hardness. WEDM

becomes a competitive and economical machining option which fulfills

the requirement of short product development cycle. This process is

affected by so many control parameters. WEDM is a complex machining

process controlled by a large number of process parameter such as

Pulse duration, Specific energy, discharge frequency and discharge

current intensity. For optimal machining performance the setting of

various input parameters plays a crucial role on output viz.

Material removal rate, Surface roughness, Kerf width, Little change

in one parameter greatly affect the output. Hence process parameter

optimization needs for variety of material. In present an attempt is

made to investigate the effect of varying pulse on time, pulse off

time, flushing pressure, servo voltage, wire feed rate and wire

tension on H-11 material to analyze effect on the Material Removal

Rate, Kerf width and Surface finish using ANOVA analysis and multi

response Taguchi base optimization will be carried out.

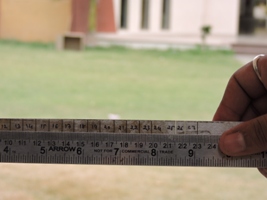

A Taguchi

design of experiment (DOE) approach with L27 Orthogonal Array

employed to conduct this experiment. Design Expert 8.0.6.1 software

was used to perform the ANOVA (analysis of Variance) and

confirmation test conducted to verify as well as compare the results

from the theoretical prediction using software. And this

dissertation work produces higher mathematical modeling; develop

software tool based on mathematical model, And develop scalar

measurement software tool in VB-6 for measurement of kerf width and

ANOVA Analyzer software tool for analysis of Variance.

Student:-

1. Savan D. Patel (130780106044)

2. Rihen B. Modi(140783119012)

3. Pranshu P. Mevada (140783119033)

4. Priyank R. Patel (130780119089)

“Automation in the canal and dam monitoring and operating

system” for real time problems were taken as a study. Various

guideline available from literature reviews, details of the study

area and suggestions and help from the irrigation departments and

practicing engineers have been taken and based on that methodology

has been developed. The problem for complete project was decided to

divide into four phases in which automation in canal monitoring,

automation in river gauge station, automation in dam and supply from

dam was taken. For this semester first and foremost phase has been

selected which includes the automation in the canal system. Also,

software based on this available information was successfully

developed for this first phase which displays and shows various

information at a same time on the screen of the PC based acquisition

system. The software system operates, monitors and manage the flow

in the river with digital display. The practical performances have

been taken in laboratory and in canal also. The planning of this

system is to installed and checked for real time monitoring and

management to supervise the control in every canal networking. The

automation will reduce state overburden over scarity of water but

also it will reduce man power control and increase remote control

over the canal.

Student:-

1. Kinnari Kapadiya(120780119090)

2. Hardik Barot(140783119002)

3. Hiren Patel(140783119036)

4. Ronak Patel(140783119038)

In modern days, all area of industries and for study used in so

we are creates the hydraulic kit our collage study for student. We

are create the hydraulic with the help of collage funding and

hydraulic kit used components is direction control valve, pressure

relief valve, storage tank, compressor etc. and main motive

development of hydraulic kit is the help of student for

training.

The hydraulics trainer kit should contain all the hydraulic elements

needed for simulating various hydraulics circuits, both simple and

advanced. The training kit should be useful for imparting practical

knowledge for the students about the fundamentals of hydraulic

system, functioning of various hydraulic elements, different

application circuits, design and function of a hydraulic system –

both basic and advanced, design and function of valves, basic

circuit diagram on practical applications, hydraulic controls with

pilot operated valves, hydraulic reservoirs, flow distributors,

commissioning and maintenance of hydraulic systems.

The kit should be supportable with textbook, exercises with

solutions, transparencies videos, workbook with exercises, cutaway

models, magnetic symbols etc.

The components should be capable of being mounted on an appropriate

Profile plate/Mounting Board with grooves for secure and flexible

positioning so that the components can be clamped firmly, quickly

and safely. The components supplied should be industrial

components.

All hydraulic components should be with self-closing, quick

connector, safety clamping and quick plug-in locking system for

Profile plate/Mounting Boards.

Student:-

1. Vaghela Amul V.(130780119103) 2. Prajapati Yash R.(130780119088)

3. Prajapati Arth N.(130780119077) 4. Parmar Chetan P.(130780119044)

Wire-cut Electrical Discharge Machining (WEDM) is extensively

used in machining of conductive materials producing intricate shapes

with high accuracy. This study exhibits that WEDM process parameters

can be altered to achieve betterment of Material removal rate (MRR),

Surface Roughness (SR). The main goals of WEDM manufacturers and

users are to achieve a better stability and higher productivity of

the WEDM process, i.e., higher machining rate with desired accuracy

and minimum surface damage. However, due to a large number of

variables and the stochastic nature of the process, even a highly

skilled operator working with a state-of-the-art WEDM is unable to

achieve the optimal performance and avoid wire rupture and surface

damage as the machining progresses.

In project work literature has been studied I context to

optimization of Wire-cut EDM. In order to attain optimal results

taguchi method employed. The appropriate orthogonal array has been

selected as per number of factors and there levels to perform

minimum experimentation. Experimental analysis of Wire-cut EDM

performs to the optimization of the machining parameters of Wire-cut

EDM machine to significantly improve optimum level of Material

Removal Rate (MRR) and Surface Roughness (Ra) in the WEDM.

The work pieces of c-45 steel materials were used for experiment

purpose. The optimum value has been determined with help of main

effect plot and ANOVA table. The Regression equation for MRR and

Surface Roughness (Ra) has been developed with the help of Minitab

17 Software.

Student:-

1. Patel Kevins Dineshbhai 2. Patel Bhavikkumar Govindbhai 3. Patel

Jaiminkumar Kanubhai 4. Patel Niravkumar Natvarbhai

In morden days, all area of industries are going to like

automated, economically and environment freely to reduce the global

warming problem. But, in production of metal by moulding process no

any wide change. Our main concept for this project is to give better

safety for all workers and to maintain good quality product and

manufacturing is environment freely to provide induction furnace and

remove coal firing furnace. Automation plant is improving the mass

production, give better quality products without any defects and

better continuity in operation. All machines are working as a part

of process. In this project, first we compare the manual foundry and

automated foundry. After we give the all details of machines and

analysis the project cost, electricity cost, investment cost and

equate the manual foundry and automated foundry. This project is

giving all useful data for plant establishment & which plant is

better far.

Student:-

1. Patel Siddharth Vishnubhai 2. Patel Jaykumar Rajendrakumar

3. Patel Pratikkumar Gajendrabhai 4. Patel Akshaykumar Satishbhai

Wire cut EDM is most progressive non-conventional machining

process in mechanical industries. There are so many parameter affect

the performance of Wire cut EDM. Few of them are investigated in

this report. In present an attempt is made to investigate the effect

of varying pulse on time, pulse off time, wire feed rate and Peak

current on H-11 material to analyze effect on the Kerf Width (KW)

and Material Removal Rate (MRR) using ANOVA analysis and multi

response Taguchi base optimization will be carried out. A Taguchi

design of experiment (DOE) approach with L9 Orthogonal Array

employed to conduct this experiment. And verify as well as compare

to the ANOVA calculation by Mathematical steps and Minitab software.

Student:-

1. Nayi Darshan Bharatkumar 2. Parmar Ravi Mahendrabhai 3. Makwana

Maulikkumar Amrutbhai 4. Luhar Suraj Chhotalal

In every school and colleges, we know that in the classroom air

is not properly circulate to around each and every student by up to

10 fans.

So to solve this problem, we are going to make movable fan with the

help of chain drive mechanism.

This project is used for classroom.

The main problem in the classroom is that the fix fans can not able

to circulate the air in whole room.

To solve this problem we are going to make movable fan with reducing

number of fan which circulate air in whole room and also save total

electricity.

Student:-

1. Prajapati Dharvishkumar Bhagavanbhai 2. Patel Urjitkumar

Ashwinkumar 3. Patel Pranavkumar Vipulchandra 4. Suthar Darshan

Bipinbhai

Nowadays, products are manufactured using modern technology

which employs a communion of computer software, hardware and

firmware and lathe machines play a vital role in the manufacturing

sector. While the manual lathe machines are economical, they require

to be operated by highly skilled workers otherwise their accuracy

and efficiency is not up to the required product. CNC machine

provide the desired accuracy and efficiency of output, but require a

huge capital. Thus upgrading the from manual to semi-automatic lathe

machines can significantly increase the accuracy and efficiency

while, at the same time, keeping a check on investment cost and

consequently provide a much needed escalation to the manufacturing

industry.

Student:-

1. Patel Ashishkumar Dashratbhai 2. Patel Apurv Jayeshbhai 3. Patel

Nirajkumar Ganpatlal 4. Bihari Jalilkhan Nyamatkhan 5. Modi

Bhauminkumar Babulal

Wire cut electric discharge machine is use for removing a material

from a work piece by use of a thin wire called as a wire electrode.

For development of our project first we collect all data related to

wire cut electric discharge machine by using research paper and

patent. We discuss on various input and output parameter of wire Cut

EDM. By using various design concepts we draw a design of wire Cut

EDM. Finally our main aim is to design and develop of wire cut

electric discharge machine with considering important parameters and

low cost.

Student:-

1. Modi Akshay Somalal 2. Joshi Bhaumik Anilbhai 3. Patel Ketulkumar

Maheshbhai 4. Patel Jatin Bharatbhai

Traffic is a problem in many urban areas worldwide. Traffic flow is

dictated by certain devices such as traffic lights. The traffic

lights signal when each lane is able to pass through the

intersection. Often, static schedules interfere with ideal traffic

flow. The purpose of this project was to find a way to make

intersections controlled with traffic lights more efficient. This

goal was accomplished through the creation of a genetic algorithm,

which enhances an input algorithm through genetic principles to

produce the “fittest” algorithm. Apart from offering other

advantageous features hydraulic actuators are first choice if heavy

loads have to be moved ,lifted or controlled this system design

hydraulic jack (actuators) operated by PLC programming for

controlling traffic according to signal sent by the program .The

time taken to change the signal light will decided by calculating

numbers of vehicles passes through.

Student:-

1. Patel Hiren K. 2. Patel Ronak D. 3. Patel Satyam K. 4. Patel Mit

S.

This project cost 43,553 Rs. Guided by Prof. Harshadkumar C. Patel

during 20th Sept to 20th Oct 2015 and total cost Sponsored By: Smt.

S. R. Patel Engineering College – Unjha.

There are three types of people in the world; poor,

middle class & high-society. High-society people have much tension

about their money and home. They have question that how they protect

their home from fire & thief. Our project is about it, how to

protect home from fire & thief. How our home is being safe?

Our project is also applicable to bank, Big company, places where

secrete data is kept, museums etc.

In This Project Include Safety from fire, Wire touching system, Wire

cutting system, Safety by lesser, Enter gate operating system, Floor

button system, Door opening by remote/code, Duplicate key informer,

Safety of door from braking, Safety of windows, Safety of

locker-room, Safety of locker, Auto dial system, Alarm system,

Calculating system,Video by camera, Auto-lock etc.

In modern days, all area of industries are going to

like automated, economically and environment freely to reduce the

global warming problem. But, in production of metal by moulding

process no any wide change. Our main concept for this project is to

give better safety for all workers and to maintain good quality

product and manufacturing is environment freely to provide induction

furnace and remove coal firing furnace. Automation plant is

improving the mass production; give better quality products without

any defects and better continuity in operation. All machines are

working as a part of process.

In this project, first we compare

the manual foundry and automated foundry. For automation control

develops new DNS software which is working as on pc is main control

and other three pc to connect with all machine and its work by main

computer software. After we give the all details of machines and

analysis the project cost, electricity cost, investment cost and

equate the manual foundry and automated foundry. This project is

giving all useful data for plant establishment & which plant is

better far.

Project Given By Sayona Engineering

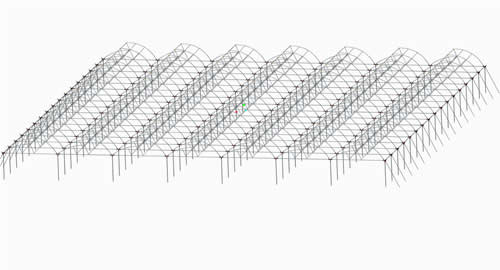

This Project

Consist Design and Analysis of Green House Structure. Project

Cost:-21,00,000/- Rs and Design cost: 21,000/- RS.

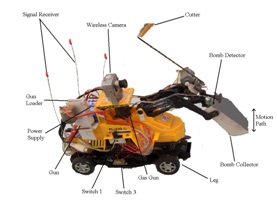

Working

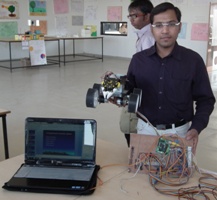

By the software, using control panel, we can operate legs of robot so that robot moves forward, backward or take left or right turn.Benefits of this Robot

Think of a creative but effective way to measure the

seismic waves (shock waves) from an earthquake. A good design would

be ...

able to determine the relative magnitude (size) of each vibration it

measures;

able to measure vibrations continuously for at least one minute;

able to measure even slight vibrations (such as a person jumping up

and down

next to your seismograph).

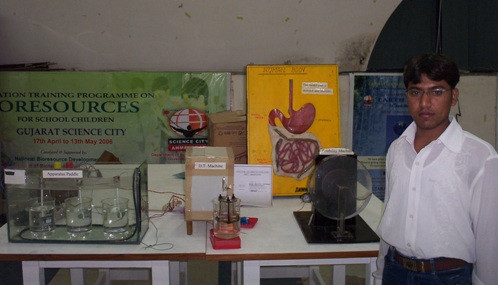

We are overjoyed to present a model which is the out

come of our level best attempts and sense. It is a model that can

test the quality of the medicines that patients have to swallow to

cure their diseases.

For example, there are many companies that provide the paracetamol

tablets in the markets with different tablets. One to different

qualities the paracetamol is available in the market which costs 50

paisa per tablet. Generally people are hardly aware about the costs

and qualities of any medicinal products. Whether the tablet contains

proper drug is a rarely soluble question among people.

Keeping the public interest in centre we have developed this device

that costs a little and benefits a lot.

This is a model or device that needs not the person with sound

knowledge of chemical or drug. An ordinary person can also use this

device to test the qualities of the medicinal tablets.

This is a device which can be prepared at the cost of about 500 to

600 rupees and that’s why if such a model or device is kept at every

health centre, school or college, it can be helpful to people in

general for testing of tablets for its qualities and people can even

know at least something about medicines. And with the help of such

common awareness among people about medicines, the drug companies

will be careful to launch their various products in the market, they

will surely try to provide qualities at a lower cost.

And doing so we can help our government and the department of drug

to decrease its financial burden.

Details Not Uploaded...

In this project, an open architecture personal

computer-based numerical control (OAPC-NC) system that can generate

G-code was developed in Visual basic 6.0 GUI software. This system

was implemented on a milling machine. A driver and an interfacing

circuit were developed in order to interface between the machine and

PC. Then, the possibility of using the developed controller for

Internet machining was also demonstrated.

In order to test the openness of the developed OAPC-NC system,

several addition functions have been added into the developed

system.

These functions include a different method of G-codes programming,

additional features for advanced machining and internet access of

the developed OAPC-NC system for Internet machining. Finally, a real

time machining is carried out as well as the roundness test on the

machined path as to test the performance of the developed

system.

As a result, an OAPC-NC system that can generate pulse generation

and G-code programming and operate a milling machine has been

developed. Besides that, the stepper motor driver circuit board that

is developed has been successfully interfaced between the PC and the

milling machine.

The OAPC-NC system can be use by a variety of NC machine.

Therefore, this system has performed the ability in factory

communication as to combine a number of difference machines.

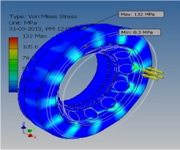

The model of gear box of plastic injection moulding machine was analyzed. There are some problems occur in plastic injection moulding machine like , wearing of gears, failure of bearing, misalignment of shaft, lack of lubrication, etc. But the major problem occur from the above is failure of bearing. This problem is occurring due to excessive axial thrust load. The analysis of two bearings, first Thrust Spherical Roller Bearing 180TS94 and second Rolling bearing 29436 was done in AUTODESK INVENTOR PROFESSIONAL 2012. It was found that the von misses stress on first bearing was higher than the second bearing. Also, the life of both the bearings was calculated mathematically. It was found that the life of second bearing is higher than the first bearing. So, the second bearing is suggested on basis of life.

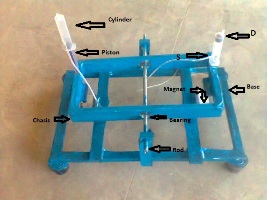

On magnetic levitation pump model I conclude that get 15 to 20 sec reciprocating is carried out. But this is not reciprocated continuously because there are some reason and this are...

Magnetic levitation isn't just for far-out technologies; it's already being used in down-to-earth applications. Industrial equipment such as pumps, generators, motors, and compressors use levitation to support moving machinery without physical contact. The levitation pump can be made up on this concept and its use in various small industries and I will try to success my model for the industry and I will work on levitation effects which is far technologies and its use in every field.

Among the natural calamities, earthquakes are the

most destructive, in terms of loss of life and destruction of

property. The rising frequency of earthquake has made it imperative

to focus our attention on all aspects of pre-disaster preparedness

from seismic studies as if we are standing on earth earthquakes do

not harm us much, but if we are standing inside a building then we

do need to worry as the brutal impact of earthquake is seen on the

buildings. So we do need to study the building and for that the

structural aspects are to be taken into consideration.

To study the structural aspects of the buildings we need to study

models of buildings , and the effect of earthquake on models can be

ana lysed by Earthquake shake table.

In this research, a uniaxial earthquake shake table that can

generate seismic waves of different frequencies equivalent to the

original earthquake is to be developed. This system is to be

implemented at original by making a working model. The possibility

of using the developed model for effect of shaking due to earthquake

on various building models can also be demonstrated.

In this

uniaxial earthquake shake table stepper motor is to be used to

provide motion to the shake table. Lead screw is to be used to give

horizontal motion to the main plate of the shake table as the lead

screw is the connection mode between the shake table and the stepper

motor.

Various models such as framed structures, structures with dampers,

village houses .etc are the case study. The effect of liquefaction

is also studied and ana lysed visually.

The city of PATAN the glorious capital of Gujarat

from 745 to 1300 A.D. is now the headquarters of PATAN district. The

rules of solanki period the constructed number of wells, libraries,

JAIN temple and learning center.

But, now in developing period

the population is so increase and the no. of vehicle also increase.

In this period every person has their own vehicle. All the person

are travelling by vehicle as like bike, scooter, bus, jeep, car,

cycle etc. So traffic controlling is required for easy travel.

As

per requirement of traffic at different places, we have visited

different intersection in PATAN and decided that the traffic signal

is required at NAVJIVAN Intersection PATAN.

Wireless sensor

networking is an emerging technology that has a wide range of

potential applications including environment monitoring, smart

spaces, medical systems and robotic exploration. In this report the

researcher tried to present the intermediate result on the design of

traffic control systems related to automobile tracking based on the

wireless sensor networks. Crossbow’s sensor network developer’s kit

(Crossbow Technology, 2003) was used as the hardware and Tiny OS

(University of California Berkeley, 2003), an operating system for

wireless sensors, was used as the software. All data collected by

the sensor nodes was aggregated at a base station. The base station

also enabled connection to a PC or a computer platform.

This

report presents the preliminary implementations of three

sub-systems: (1) safe vehicular passing, (2) traffic violation

detection, and (3) automobile tracking. Safe vehicular passing was

developed to serve rural roads where many accidents happen during

passing maneuvers. This application allows the users to acquire

knowledge of the surroundings to enhance vehicular passing safety.

Traffic violation detection was developed to capture traffic

violations with minimal costs. In this application light sensors

were used to either count traffic or to detect a violation. Many

assumptions were made when developing the automobile tracking

system, but these assumptions can be implemented with the

sophisticated equipment available.

We have done this project by

manual method and provide a working model of the signal at

intersection.

In last forty years there is tremendous research in

machining and development in technology. With increase in

competition in market and to attain high accuracy now a days the non

conventional machining are become lifeline of any industry. One of

the most important non conventional machining methods is Plasma Arc

Machining. Its high accuracy, finishing, ability of machining any

hard materials and to produce intricate shape increases its demand

in market.

In thesis work literature has been studied in context to parametric

optimization of Plasma Arc Cutting Machine. In order to attain

target and optimum results, Taguchi method employed. The appropriate

orthogonal array has been selected as per number of factors and

there levels to perform minimum experimentation.

The work pieces of alloy steel EN 31 materials were used for

experiment purpose. The optimum value has been determined with the

help of main effect plot and ANOVA table. The Regression equation

for MRR and Surface Roughness (Ra) has been developed with the help

of Minitab 15 Software.

In order to produce any product with desired quality by machining, proper selection of process parameters is essential. This can be accomplished by Full Factorial method. The aim of the present work is to investigate the effect of process parameter on surface finish and material removal rate (MRR) to obtain the optimal setting of these process parameters and the analysis of variance is also used to analysis the influence of cutting parameters during machining. L27 experimental runs based on an orthogonal array of full factorial method were performed. Additionally the analysis of variance (ANOVA) is also applied to identify the most significant factor. During the experimental process parameters such as speed, feed and depth of cut are used to explore their effect on the surface roughness (Ra) of the work piece. This work presents an experimental investigation of influence of the three most important machining parameters of Speed, Feed and Depth of Cut on surface roughness during turning of AISI D2 steel. In this work AISI D2 steel work pieces are turned on conventional all gear lathe by using carbide tool. The result indicated that the process parameter cutting speed feed rate and combination of both parameters have significant effects on surface quality of turning of AISI D2 steel. From ANOVA analysis surface roughness is mostly affected by cutting speed and feed rate so that surface roughness can be improve by decreasing the feed rate as well as increasing the cutting speed up to 66 m/min and after increasing cutting speed surface roughness decrease.

Electrical Discharge Machining (EDM) is one of the earliest non-traditional machining processes. EDM process is based on thermoelectric energy between the work piece and an electrode. Material Removal Rate (MRR) and surface roughness is an important performance measure in EDM process. Since long, EDM researchers have explored a number of ways to improve and optimize the Response parameter including some unique experimental concepts that differs from the traditional EDM sparking phenomenon. Despite a range of different approaches, all the research work in this area shares the same objectives of achieving more efficient material removal coupled with a reduction in tool wear and improved surface quality. The project reports on EDM relating to improvement in MRR and SR along with some insight into mechanism. In the end of the paper, scope for future research work has been outlined.

Wire electrical discharge machining process is a highly complex , time varying & stochastic process. The process output is affected by large no of input variables. Therefore a suitable selection of input variables for the wire electrical discharge machining (WEDM) process relies heavily on the operators technology & experience because of their numerous & diverse range. WEDM is extensively used in machining of conductive materials when precision is of prime importance. Rough cutting operation in wire EDM is treated as challenging one because improvement of more than one performance measures viz. Metal removal rate(MRR), surface finish & are sought to obtain precision work. In this paper an approach to determine parameters setting is proposed. Using Taguchi’s parameter design , significant machining parameters affecting the performance measures are identified as pulse peak current , pulse on time, and duty factor . The effect of each control factor on the performance measure is studied individually using the plots of signal to noise ratio. The study demonstrates that the WEDM process parameters can be adjusted so as to achieve better metal removal rate, surface finish.

In present era engineers are trying to reduce the use of conventional sources but there are still some places like Hindu Crematoria where we can’t avoid using wood. No one is paying attention on reducing the carbon coming out from crematoria. We can not change the rituals of Hindu religion but can modify it by using modern techniques. We selected this project to separate carbon content from exhaust of crematoria and to make cremation environment friendly. This project will reduce pollution up to 75% as compare to normal cremation.

Details Not Uploaded...

By the help of this instrument we can automatic measure the rainfall. Only put this instrument at different places where we want and connect rain measurement software with internet connection. we can calculate the how much rain is fall at particular year,month,day, hour and place we can also generate the reports well as graphs , can print also.

Details Not Uploaded...

Details Not Uploaded...

In ginning industries the most common problem is the roller, first of take away roller from gin machine and set on roller cutting machine, the motor is on base which is on sliding bearing so. when the motor is start with the help of high skilled labor the base is moving reciprocating so with this reciprocating moment the spiral cut is going on roller and it is totally manual work and machine is stopped until roller is spiral so it is taking so much time with this process. this process stop works until roller is not get spiral. Although it is long process but is not accurate also and it required high skilled labor the time waste is different. After modified Design, Depth of cut is very accurate in spiral, the gap of spiral is very precious so that production rate is increase and the preparing time of roller is decrease because of automatic principal.

Details Not Uploaded...

Electric discharge machine is use for removing a material from a work piece by use of a Limited Diameter Electrode. For development of our project first we collect all data related to electric discharge machine by using research paper and patent. We discuss on various input and output parameter of EDM. By using various design concept we generate 3-d drawing of EDM in CREO 2.0. We optimize our design model and applied automation. Our main aim of project is to develop a EDM machine for a College Laboratory Purpose where college student gain Basic and practical knowledge about Electric discharge machine and we also try to made machine with better feed accuracy than markets’ machines. So for fulfillment of our aim we try to optimize feed accuracy up to micro level with accurate Pulse ON/OFF time in low power supply and moderate cost.

More often than not, when He set about writing a paper, they spend the most time on the "meat" of the article (the methods, results, and discussion sections). Little thought goes into the title and abstract, while keywords get even lesser attention, often being typed out on-the-spot in a journal's submission system. Ironically, these three elements—the title, abstract, and keywords—may well hold the key to publication success.

Granted

Granted

Granted

FER Generated

Here Include Different Type Activities like FDPs, Workshops, Training's, Event Participation's, Seminars etc.

Selected from Level I (Ideation) to Level II (Proof of Concept)

Adducation-1...

Adducation-2...

at Pune on 1st to 3rd March 2018. Rank-18 out of 125 Colleges

Adducation...

at Pune on 1st to 3rd March 2018. Rank-18 out of 125 Colleges

Adducation...

at Pune on 1st to 3rd March 2017.

Adducation...

at Pune on 3rd to 5th March 2016.

Adducation...

at Darshan Institute of Engineering & Technology, Rajkot on 31st August

To 1st September 2012 in Eureka Events.

Project:- Auto Rain Measurement

Adducation...

at Darshan Institute of Engineering & Technology, Rajkot on 31st August

To 1st September 2012 in Eureka Events.

Project:- Advance Home

Security System

Adducation...

at Pacific Center For Indigenous Technology on 18th To 19th April 2012

in Events.

Project:- Auto Rain Measurement

Adducation...

at Pacific Center For Indigenous Technology on 18th To 19th April 2012

in Events.

Project:- Auto Missile Launcher

Adducation...

at Pacific Center For Indigenous Technology on 18th To 19th April 2012

in Events.

Project:- Safety Home

Adducation...

at School Of Engineering, RK. University, Rajkot on 24th March 2012 in Pro/E Events. Adducation...

at School Of Engineering, RK. University, Rajkot on 24th March 2012 in

Project Competition Events.

Project:- Auto Missile Launcher

Adducation...

at School Of Engineering, RK. University, Rajkot on 24th March 2012 in

Project Competition Events.

Project:- Computerized Seismograph

Adducation...

at School Of Engineering, RK. University, Rajkot on 24th March 2012 in Knowledge Way Events (Paper Presentation) Adducation...

at Laljibhai Chaturbhai Institute Of Technology, Bhandu on 16th To 17th April 2011 in Robowar Events. Adducation...

at Laljibhai Chaturbhai Institute Of Technology, Bhandu on 16th To 17th

April 2011 in Project Competition Events.

Project:- Auto Missile

Launcher

Adducation...

at U. V. Patel College Of Engineering, Kherva on 25th To 26th March 2011

in Automate Events.

Project:- Auto Missile Launcher

Adducation...

at U. V. Patel College Of Engineering, Kherva on 25th To 26th March 2011

in Automate Events.

Project:- Auto Rain Measurement

Adducation...

at U. V. Patel College Of Engineering, Kherva on 25th To 26th March 2011 in Robotics - Rescue Roboz Events. Adducation...

at L. D. College of Engineering, Ahmedabad on 8th & 9th March 2011 in Be A CAD Pro Events. Adducation...

at L. D. College of Engineering, Ahmedabad on 8th & 9th March 2011 in Open hardware Events. Adducation...

at L. D. College of Engineering, Ahmedabad on 8th & 9th March 2011 in Papyrus Events. Adducation...

at L. D. College of Engineering, Ahmedabad on 8th & 9th March 2011 in

Open hardware Events.

Project:- Auto Rain Measurement

Adducation...

at Maharaja Sayajirao University of Baroda on Feb 2011 in Open X

Events.

Project:- Auto Missile Launcher

Adducation...

at Vishwakarma Govt. Engineering College, Chandkheda, Gandhinagar on 8th

& 9th April 2010 in Open hardware Events.

Project:- Computerized

Pick and Place Robot

Adducation...

at L. D. College of Engineering, Ahmedabad on 23rd To 24th February 2010

in Open hardware Events.

Project:- Computerized Pick and Place Robot

Adducation...

at The Maharaja Sayajirao University of Baroda on 22th To 24th February

2008 in Open Hardware Events.

Project:- Automatic Foundry

Adducation...

at L. D. College of Engineering, Ahmedabad on 12th To 13th February 2007

in Open hardware Events.

Project:- Rakshitalym ( Advance Home

Security System )

Adducation...

at L. D. College of Engineering, Ahmedabad on 12th To 13th February 2007

in Open hardware Events.

Project:- Journey Of Advance Foundry System

Adducation...

at The Maharaja Sayajirao University of Baroda on Feb 2006 in Horizon

Events.

Project:- Tablet Analysis

Adducation...

at L. D. College of Engineering, Ahmedabad on 23rd To 24th February 2006

in Open hardware Events.

Project:- Tablet Analysis

Adducation...

at Atmiya institute of Technology & Science, Rajkot on 9th To 10th

October 2005 in Project Competition Events.

Project:- Rakshitalym (

Advance Home Security System )

Adducation...

at Jilla Shikshan Talim bhavan Mehsana on 8th To 10th january 2003. Adducation...

by Department of Mechanical Engineering, U. V. Patel College of Engineering, Ganpat University on 05 May 2025. Adducation...

by Department of Mechanical Engineering, U. V. Patel College of Engineering, Ganpat University on 25 April 2025. Adducation...

at Ganpat University on Oct 2024 to March 2025. Adducation...

jointly organized by regional office- GPCB Mehsana, M/S Basant Cleaneviro Limited and Ganpat University on 5th June, 2024. Adducation...

at JNV, Vadnagar on 18th & 19th July, 2024. Adducation...

Organized by Ganpat University- UVPCE, Kherva on 14th & 15th October, 2022. Adducation...

at Shubh Academy, Gandhinagar on 11th Dec 2022. Adducation-1... Adducation-2...

Organized by Goverment Polytechnic, Vadnagar on 7th Oct 2022. Adducation...

Organized by Ganpat University- UVPCE, Kherva on 6th Sept 2022. Adducation...

Organized by Goverment Polytechnic, Vadnagar on 28th Oct 2020. Adducation...

Participated Students from diploma colleges Organized by Smt. S. R. Patel Engineering College, Unjha and Collabrative with Kohodiyar CAD Center Pvt. Ltd. on 14th and 15th Feb 2020. Adducation...

Participate Students from Goverment Polytechnic-Palanpur, K. D. Polytechnic-Patan and SPB Patel Engineering Colleg-Mehsana organized by Smt. S. R. Patel Engineering College, Unjha on 6th Feb 2020. Adducation...

Participate Students from Goverment Polytechnic, Vadnagar Organized by Smt. S. R. Patel Engineering College, Unjha on 5th Feb 2020. Adducation...

Organized by Smt. S. R. Patel Engineering College, Unjha on 18th January 2020. Adducation...

Sponsered by GUJCOST, Gujarat and Organized by Smt. S. R. Patel Engineering College, Unjha on 23rd - 25th December 2019. Adducation-1... Adducation-2...

Organized by Smt. S. R. Patel Engineering College, Unjha on 21st - 23rd August 2019. Adducation...

Associated by Embed Tech, Mehsana and Organized by Smt. S. R. Patel Engineering College, Unjha on 19th - 21st July 2019. Adducation...

Organized by Smt. S. R. Patel Engineering College, Unjha on 13th -14th June 2019. Adducation...

At Smt. S. R. Patel Engineering College, Unjha on 15th April 2019. Adducation...

At Smt. S. R. Patel Engineering College, Unjha on 2rd April 2019. Adducation...

Sponsered by GUJCOST, Gujarat and Conducted by Khodiyar CAD Center, Mehsana on 22nd & 24th Feb 2019. Adducation...

Organized by Smt. S. R. Patel Engineering College, Unjha for students of Goverment Polytechnic, Palanpur on 14th & 15th Feb 2019. Adducation...

Organized by Smt. S. R. Patel Engineering College, Unjha on 12th Jan 2019. Adducation...

Deliver by Malwa CAD Center at Smt. S. R. Patel Engineering College, Unjha on 15th and 16th Sept 2018. Adducation...

for 1at year students of Smt. S. R. Patel Engineering College, Unjha on 12th and 13th July 2018. Adducation...

at Smt. S. R. Patel Engineering College, Unjha on 6th and 7th June 2018. Adducation...

at Bhagwati International Public School, Patan on 4 Feb 2018. Adducation...

at Babaria Institute of Technology, Baroda on 5 Feb 2018. Adducation-1... Adducation-2...

organized by Smt. S. R. Patel Engineering College during 1st to 3rd January 2018. Adducation...

at Smt. S. R. Patel Engineering College - Unjha supported by Embetech Company,mehsana Sponsored by GujCost during 25th to 27th August 2017. Adducation-1... Adducation-2... Adducation-3...

at Smt. S. R. Patel Engineering College - Unjha for Computer Branch Student during 21st and 31st July 2017. Adducation...

at Smt. S. R. Patel Engineering College - Unjha for Civil and Mechanical Student during 14th and 17th July 2017. Adducation...

organized by Smt. S. R. Patel Engineering College during 22nd to 24th June 2017. Adducation...

Organized by Smt. S. R. Patel Engineering College during 10th and 11th April 2017 for Goverment Polytechnic, Himmatnagar Students. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 7th April 2017. Adducation...

Organized by Smt. S. R. Patel Engineering College during 8th and 9th March 2017 for Goverment Polytechnic, Palanpur Students. Adducation...

Organized by Smt. S. R. Patel Engineering College during 8th and 9th March 2017 for R. C. Technical Institute, Ahmedabad Students. Adducation...

Organized by Smt. S. R. Patel Engineering College during 7th March 2017 for Goverment Polytechnic, Vadnagar Students. Adducation...

Organized by Smt. S. R. Patel Engineering College during 3rd March 2017 for K. D. Polytechnic, Patan Students. Adducation...

Organized by Smt. S. R. Patel Engineering College during 17th Sept 2016. Adducation...

sponsored by Entrepreneurship Development Institute of India (EDI), Gandhinagar and organized by Smt. S. R. Patel Engineering College during 25th-27th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 27th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 23rd July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 20th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 16th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 13rd July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 9th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 7th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 2nd July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 25th June 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 29th June 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 22nd June 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 18th June 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 16th June 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 13th,14th,20th and 21st July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 18th July 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 2nd and 3rd Jun 2016. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 11th April 2016. Adducation...

at L.D. College of Engineering - Ahmedabad during 27th To 28th March 2015. Adducation...

at SRPEC - Unjha during 21st To 25th December 2015. Adducation...

at Prakrust-2015 organize by SRPEC - Unjha during 25th To 26th September 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 16th To 24th July 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 6th July 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 29th June 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 18th April 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 17th To 18th April 2015. Adducation...

at Smt. S. R. Patel Engg. College, Unjha. during 4th April 2015. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 3rd January 2014. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 24th To 25th January 2013. Adducation...

at Smt. S. R. Patel Engineering College - Unjha during 19th To 10th February 2012. Adducation...

at Government Engineering College - Bhuj during 5th & 6th April 2008. Adducation...

at Government Of Gujarat, Kutchch during 16th To 18th October 2005. Adducation...

Organized by Kilachand Devchand Polytechnic, Patan from 16/12/2024 to 21/12/2024 (One Week). Adducation-1 Adducation-1(PDF)

Organized by Department of Artificial Intelligence & Data Science, Vishwakarma Institute of Technology, Pune from 12/02/2024 to 17/02/2024 (One Week). Adducation-1 Adducation-1(PDF)

Organized by GUNI - Faculty of Engineering and Technology in association with Association of Indian Universities (AIU), GUNI-Internal Quality Assurance Cell & Institution’s Innovation Council. from 13/07/2024 to 19/07/2024 (One Week). Adducation-1 Adducation-1(PDF)

Under the Department of Science & Technology, JNTUK University College of Engineering Narasaraopet, Andhra Pradesh in collabrotion with Brainvision Solutions India Pvt. Ltd and AICTE from 21/08/2023 to 25/08/2023 (One Week). Adducation-1 Adducation-1(PDF)

Under the Department of Science & Technology, GUJCOST (Govt. of Gujarat) organized by Applied Sciences and Humanities Department, Parul University, Limda from 15/10/2022 to 20/10/2022 (One Week). Adducation-1

Conducted by B and B institute of technology, Vallabh Vidyanagar Under of NITTTR, Chandighad, India from 19/09/2022 to 23/09/2022 (One Week). Adducation-1

Organized by Department of Information Technology and Department of Computer Science and Engineering at IMS Engineering College, Ghaziabad, Uttar Pradesh held on 1st to 5th August, 2022. Adducation-1

Delivered by Prof. Chris Hutchison, Dy. Vic-Chancellor (Research & Innovation) Federation University, Australia and Organised by GUNI-Centre for International Alliances held on 1st to 27th July, 2022. Adducation-1

Organized by Govind Guru Tribal University at University College of Engineering, Banswara held on 25th to 29th July 2022. Adducation-1

Organized by GUNI-Department of Mathematics, Kherva held on 25th to 30th July 2022. Adducation-1

organized by IndiaSoft Technologies(P) Ltd., Pune. held on 8th August 2020. Adducation-1

organized by Department of Mechanical Engineering, GLA University, Mathura in association with Indian Institute of Metals (IIM), Mathura Chapter during 19th and 24th July 2020. Adducation-1 Adducation-2 Adducation-3

organized by Smt. S. R. Patel Engineering College, Unjha during 13th and 14th June 2019. Adducation...

organized by EDII and SSIP Cell, Education Department at EDII Campus sponsored by Gujarat Knoledge Society (GKS) during 17th to 21st December 2018. Adducation...

organized by the Department of Mechanical Engineering of SRPEC, Unjha during 21st to 24th April 2018. Adducation...

by GTU in association with National Instrument" at GIC, Ahmedabad. on 18th Sept 2015. Adducation...

at GTU, GIC-S4-Co Creation Centre, Ahmedabad. during 21st April 2015. Adducation...

at GTU, GIC-S4-Co Creation Centre, Ahmedabad. during 9th to 11th March 2015. Adducation...

at GTU, GIC-S4-Co Creation Centre, Ahmedabad. during 31th January To 2nd February 2015. Adducation...

at GTU, GIC-S4-Co Creation Centre, Ahmedabad. during 10th To 12th November 2014. Adducation...

at Gujarat Power Engineering And Research Institute, Mehsana during 21st June 2014. Adducation...

at Dhyey Training Academy & placement Consultant, Ahmedabad during 21st June 2013. Adducation...

Organized by Department of Electrical Engineering, Dream Institute of Technology, Kolkata during 09th to 15th May 2024. Adducation...

GUNI-Internal Quality Assurance Cell and GUNI-Centre for Advanced Research Studies in association with AIU- Ganpat University (GUNI) - Academic & Administrative Development Centre (AIU-GUNI AADC) during 19th to 23th March 2024. Adducation...

Oraganized by Smt. S. R. Patel Engineering College, Unjha during 13th to 18th Nov 2017. Adducation...

Sponsored by GUJCOST, Gandhinagar during 24th to 26th June 2017. Adducation...

Organized by IIT Indore in collaboration with Electronics and ICT Academy Jabalpur, at Indian Institute of Technology, Indore during 19th to 23rd December 2016. Adducation...

Sponsored by GUJCOST, Gandhinagar during 5st To 9th December 2016. Adducation...

at Smt. S. R. Patel Engineering College, Unjha. during 21st To 25th December 2015. Adducation...

at Smt. S. R. Patel Engineering College, Unjha. during 29th November To 3rd December 2014. Adducation...

Organized by Applied Science and Humanities Department, Parul Polytechnic Institute, FOET, Parul University, Limba on 27 Jan 2024 and 3 Feb 2024. Adducation...

Organized By Ganpat University on 12th October, 2023. Adducation...

Organized By Ganpat University-Department of Social Work & CARS as on 26th November, 2022. Adducation...

Organized By CIPET-IPT-Ahmedabad on 4 & 5 Dec, 2018 held at CIEPT: Institute of Plastics Technology(IPT), Ahmedabad Adducation...

Conducted by Malwa CAD Centre on 15 & 16 Sept, 2018 held at Smt. S. R. Patel Engineering College, Unjha Adducation...

Conducted by IIT-Bombay on 18 & 19 November, 2016 held at Institute of Infrastructure, Technology, Research and Management (IITRAM), Ahmedabad Adducation...

by NCVT, Ahmedabad at Smt. S. R. Patel Engineering College, Unjha On 7th August 2016. Adducation...

by Library and Knowledge Center, Smt. S. R. Patel Engineering College, Unjha On 5th June 2016. Adducation...

by Automation & Embedded Training Center (AETC), Ahmedabad. during Prakrusht 2015 Event On 26th Sept 2015. Adducation...

by Automation & Embedded Training Center (AETC), Ahmedabad. during 25th July 2015. Adducation...

at Gujarat Technological University, Ahmedabad. during 22nd To 23rd April 2015. Adducation...

at Smt. S. R. Patel Engg. College, Unjha. during 4th April 2015. Adducation...

at Gujarat Technological University, Ahmedabad. during 7th and 8th March 2015. Adducation...

at L. C. Institute of Technology, Bhandu ( Mehsana ) during 29th september 2012. Adducation...

at U. V. Patel College of Engineering, Kherva during 23rd February 2011. Adducation...

Organized by Department of Commerce and Library of Yashwantrao Chavan College, Ambajogai, Dist: Beed on 16th April 2024. Adducation

Organized by Ganpat University, Acharya Motibhai Patel Institute of Computer Studies as on 22nd Feb 2024. Adducation

Organized by Yashwantro Chavan College, Ambajogai, Maharashtra as on 16th Jan 2024. Adducation

Conducted by ARCNET India and CliMed Research Solution, India as on 31st Jan 2024. Adducation

Organized by Dr. S. & S. S. Ghandhy GEC, Surat in Joint Collaboration with Association of Mutual Funds in India (AMFI) as on 29th Jan 2024. Adducation

Organized by GEC, Palanpur and GEC, Dahod in Joint Collaboration with Association of Mutual Funds in India (AMFI) as on 31st Jan 2024. Adducation

Organized by Department of Science & Humanities, Swarrnim Institute of Technology, Swarrnim Startup & Innovation University, Gandhinagar as on 8th August 2023. Adducation

Organized by Ganpat University-Department of Social Work as on 6th July 2023. Adducation

Organized by Ganpat University - FOET as on 21st Feb 2023. Adducation-1 Adducation-2

organized by Automation Studio as on 21st Feb 2023. Adducation-1 Adducation-2

organized by Automation Studio as on 16th Feb 2023. Adducation-1 Adducation-2

organized by Automation Studio as on 14th Feb 2023. Adducation-1 Adducation-2

organized by Ganpat University-Department of Social Work as on 25th Feb 2023. Adducation-1 Adducation-2

Under National Intellectual Prperty Awareness Mission organized by Intellectual Property Office, India on 28 January 2023. Adducation-1 Adducation-2

Organized Autodesk Authorized Training Center held on 24th Dec 2022. Adducation...

Under National Intellectual Prperty Awareness Mission organized by Intellectual Property Office, India on 08 September 2022. Adducation-1

Organized by e-Yantra Lab Setup Initiative (eLSI), Indian Institute of Technology, Bombay held on 12th Sept 2022. Adducation...

Organized by Institution’s Innovation Council (IIC), GSFC University, Vadodara Supported by MoE’s Innovation Cell (MIC), AICTE and GUIITAR Council held on 28th July 2022. Adducation...

Organized by by Shri Satsangi Saketdham “Ram Ashram” Group of Institutions, Vadasma during 23rd May 2020. Adducation...

Organized by Council of Library & Information Science (COLIS), Gandhinagar during 7th May 2020. Adducation...

Hosted by Silver Touch Techlab Team by GTU during 23rd April 2020. Adducation...

Organized by Council of library and information science, Gandhinagar during 23rd April 2020. Adducation...

through Zoho Technologies during 9th April 2020, 6 to 9 pm.. Adducation...

at U. V. Patel College Of Engineering, Kherva during 16th To 17th January 2015. Adducation...

at U. V. Patel College Of Engineering, Kherva during 18th To 19th December 2010. Adducation...

from Bosch Rexroth-Center of Excellence, Ganpat University Approved by CED, Government of Gujarat during 5th Sept 2023 to 25th Nov 2023. Adducation...

from TEERTH initiative of Knowledge Consortium of Gujarat, Govt. of Gujarat during 26th Dec 2022-12th Jan 2023. Adducation...

from authorized institute in Moment Education & Research Foundation- Visnagar during Oct-2018 to Dec-2018. Adducation...

Conducted as a part of Teacher Training Through the e-Yantra Lab Setup Initiative (eLSI), IIT, Mumbai during 10th January 2017 to 5th April 2017. Adducation...

at Paras, Ahmedabad during October 2008 To December 2008. Adducation...

at Rakshak Computer, Bhuj during 7th May 2007. Adducation...

I also worked on Machine Design and Analysis, CNC Program, Automation Program, Software and Website Development etc.

I very well Know... |

||||

|

|

|

Some Useful Material for Engineering Students.

My Life with My Family and My Friends also with Professional.

Also Cover News

Paper Cutting and TV News

C28, Vatsalya City, Detroj Road

Ta-Post:- Kadi (382715)

Dist:-

Mehsana

State:- Gujarat

Country:- India

UVPCE, Ganpat University, Kherva

Dist:- Mehsana

State:-

Gujarat

Country:- India

I am at my office every day from 9:00 am until 4:00 pm, but you may consider a call to fix an appointment.